A month ago, I asked Sakari to break down the various types of drags. He's a wealth on the Board when it comes to reels. He's torn apart the basic types as well as variants and other great features. Let's hope he can get all these pieces back together. I have a feeling he'll have them running and pulling in salmon by morning. ~Eric

The Click Drag (Click & Pawl)

I'll start with the perhaps most traditional type of "drag" - the click drag. A click drag is basically a toothed gear that revolves with the spool and against a spring-loaded click pawl or spring clip. As the gear revolves, the pawl is dragged over the teeth of the gear. By far, the most common click drag system is a separate gear on the spool that rotates against spring-loaded pawl or pawls. However in some reels, like the Sage 3000 series click & pawl, the inside of the spool is in itself the gear. And on others, like the Lamson Litespeed, the clip is attached to the spool, and thus it is rotated around the stationary gear of the center hub. This holds the real drag system of the reel; the clicker is just for sound.

The drag force a click drag reel can produce is small and is in effect both directions, so these reels don't have to be left or right handed. The click pawl reel's drag most important function is to prevent overspooling - and notifying other fishermen that you're hooked a fish.

The Draw Bar Disc Drag

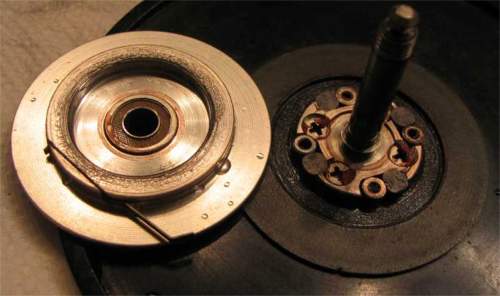

Perhaps the most common drag in modern reels is the draw bar disc drag. In this system two or more circular discs are compressed against each other, and at least one of the discs can rotate only one direction. In many reels the other disc is actually the backside of the spool onto which a drag material, designed to give good drag performance, can be placed.

Other disc drags can have pins pressed against a drag disc or have a sort of brake caliper like in cars where the disc is pressed between friction material pads. The drag disc freely rotates in one direction, but in the other, friction from the pins or pads inhibits the rotation creating drag force.

There are also variants of the disc drag, for example in Waterworks/Lamson reels. Instead of planar discs, the drag surfaces are conical. This solution increases drag surface compared to planar discs of the same diameter, but not that much - unless the cones are really tall however that would easily lead to sticking problems.

Drag Varients

Danielsson reels have a type of anti-overspooling system that consists of six conical bushings placed on bearings. The cones are pressed via the bearings against the spool, and thus a rolling resistance is created. This system creates a sort of whirring sound and affects both ways just like click and pawl reels. This enables very light reels, but personally, I hate the extra resistance in winding and miss the clicking sound. There are other reels, like Marco reels, that use the same basic idea, but with different geometry.

STH has a unique turbine drag that relies on a spinning wheel in a fluid. The great thing in this type of drag is that there is absolutely no startup inertia. The downside is that it is not possible to adjust the resistance of this type of drag. The drag, according to STH, reaches a drag level close to its maximum very rapidly and keeps quite constant regardless of rpm - unless it gets very low. This system protects fine tippets because when the fish is taking off, the drag is at a very low setting basically, but will still inhibit overspooling. Accompanied with a disc drag for example it can be great assistance preventing overspooling and protecting tippet during the initial stages of a fish's run.

In addition to disc drags, just like cars, fly reels can have drum brake type drags. Actually some very highly regarded salmon reels use drum drag. In these, brake shoes are pressed against revolving cylinder. This design is simple, and the rotation itself can be used to press the brake shoe to the cylinder - this makes the required external pressure smaller compared to disc drags for example.

Rotation Control

In many drags, a part needs to be prevented from rotating in one direction. The most traditional way is a spring-loaded pawl or a spring-loaded pin that jumps from one valley to another. Either the teeth are formed in such a way that the pawl or pin can only move one direction, or the gear teeth are similar both directions with the shape of the pawl preventing rotation in one direction. For example, Tibor or Abel, they have pawls that stop the drag gear plate (Abel's system). Switching the pawl to face the other direction, the winding direction of the reel is changed.

Instant Anti-Reverse (IAR)

Nowadays Instant Anti Reverse, IAR, is found in many reels. It is often a cheap solution that engages the drag instantly. Most of these reels rely on IAR bearing (also known as a one way clutch or one way bearing). The inner race of the bearing grabs the shaft when rotating in one direction. By turning the IAR bearing around, the reel winding direction is changed. Basically the bearing is a roller bearing, but the spring-loaded cylinder-shaped rollers are wedged between their housing and the shaft if tried to rotate backwards. Bauer builds their IAR-system into the drag plate and the base of the shaft.

Direct Drive, Anti-Reverse & Dual Mode Winding

Most reels are direct drive, but there are anti reverse and dual mode reels out there too. On direct drive reels, the handle is attached directly on the spool. If a fish takes off, you may end up with busted knuckles. Direct drive has loads of feel, and you know what the fish is doing.

In anti-reverse reel there is a separate arm, or a disc, onto which the handle is attached. The arm or disc is attached to the drag plate that only rotates one direction, so when the fish runs the handle stays put. When winding an anti-reverse reel, you essentially rotate the drag plate, and the drag setting defines the force you exert unlike in direct drive. If fish takes line slipping the drag, you can retrieve all you want, the fish won't know it.

Dual mode is a combination of direct drive and anti-reverse and utilizes the best part of each. When a fish takes line, the handle won't turn, just like in anti-reverse reels. However if you start winding, it instantly transfers into direct drive. You won't bust your knuckles, but you can force the fish if you want to. Dual mode actuating usually relies on the same principles as IAR bearings. There are wedging spaces, which hold either balls or cylinders. Once the handle is rotated in the winding direction, the cylinders or balls are wedged and locked between the different parts of the system creating the direct drive. Releasing the force on the handle releases the system.

Drag Materials

The material used in a drag is another important subject, a subject that really divides opinions. Some like graphite drags, some cork, some Teflon or Rulon, or whatever. Start-up friction is not desired, but materials with low start-up friction have low sliding friction too. A low sliding friction requires a high compressive force if a powerful drag is needed.

Impregnated cork is a traditional material and has quite well stood the test of time. The great thing about it is that it is compressive, which makes is it a forgiving material (a small fuck-up in the design may not cause the reel to jam as might happen with a different material). Cork is essentially a drag material and spring in one. As it is compressive, its ramp-up to the set drag force is fairly long compared to other materials. This should protect the tippet, but I personally think it doesn't matter in the real world. The ramp-up takes only perhaps one degree of spool rotation anyhow. Cork is can be used against many materials, but it needs to be properly impregnated with lubricant to be smooth. It also needs maintenance, so it's not very suitable for sealed drags.

Graphite to stainless steel drags are very common in the reels of today. The friction coefficient is low, and the start up inertia is basically non-existent. Teflon, rulon and other low friction plastics are also good for low start-up friction - they essentially have none and don't need lubrication.

Many manufacturers state that their drag is the bee's knees because the same material is used in fighter plane brakes or in F1-car brakes. The problem with that connection is that the carbon-carbon composites in those brakes are used in completely different way. The temperature is much higher and in those temperatures the friction coefficient is not low. On the contrary, it is in fact very high which is what is sought after because the vehicle must be stopped quickly. You don't want to use reel material in the same manner as in F1 brakes - suddenly the drag force of your reel would go from 5lb to 50b or even higher in the middle of a fish's run. You'd think your reel had jammed.

A good drag can be made out of any of the materials mentioned above and out of many I've left out. If a powerful drag is needed, size matters, especially if a smooth drag is desired. A small drag with high drag force means heat accumulation problems. And even with big drags, the heat has to go somewhere. Often the spool is used as heat sink. With cork and plastics, it is crucial as these can easily reach the overheating temperature. If you're after big fish that run long and hard you should also think how the drag handles an extended battle.

Sealed or not?

Sealed reels are easy, as you know you can't get sand or salt inside. On the other hand, if something should go wrong an open system is easy to overhaul. Plus an open system is also quite easy to wash. A sealed system also narrows down the choice of drag materials.

Silent or not?

Some reels are silent winding and silent out going. Some have sound when retrieving and when line is going out or a combination in between too. The main thing is what you like. Or dislike. There are many ways to produce sounds but as long as they are done well, they shouldn't have any effect on the reels behavior.

The Drag Knob

It should be easy to turn, but it shouldn't turn by accident. It should be easy to grab but not in the way or catch the line often. On bigger reels, I like Bauer's decision to place the star knob inside the spool. If the space were smaller I wouldn't want to put my fingers in to adjust the drag.

The world is full of options - you'll just need to find the one that suit you. Or two. Or three, maybe four, why not five…

January '08

Sakari is from Helsinki and catches salmon. He's also a materials engineer when real life catches him.